There is a growing body of evidence that Diesel fuel passing through fuel metering and pressure control nozzles in high pressure Diesel fuel injection equipment is subjected to tribological stress, which is able to alter the composition of the Diesel fuel being returned back to the fuel tank. The evidence suggests that a fraction of the aromatic molecules comprising the Diesel fuel are subject to collisional excitation, facilitating molecular combination reactions that are able to result in the formation of polycyclic aromatic hydrocarbons (PAHs). These PAHs are precursors to the formation of primary soot-like nano-particles.

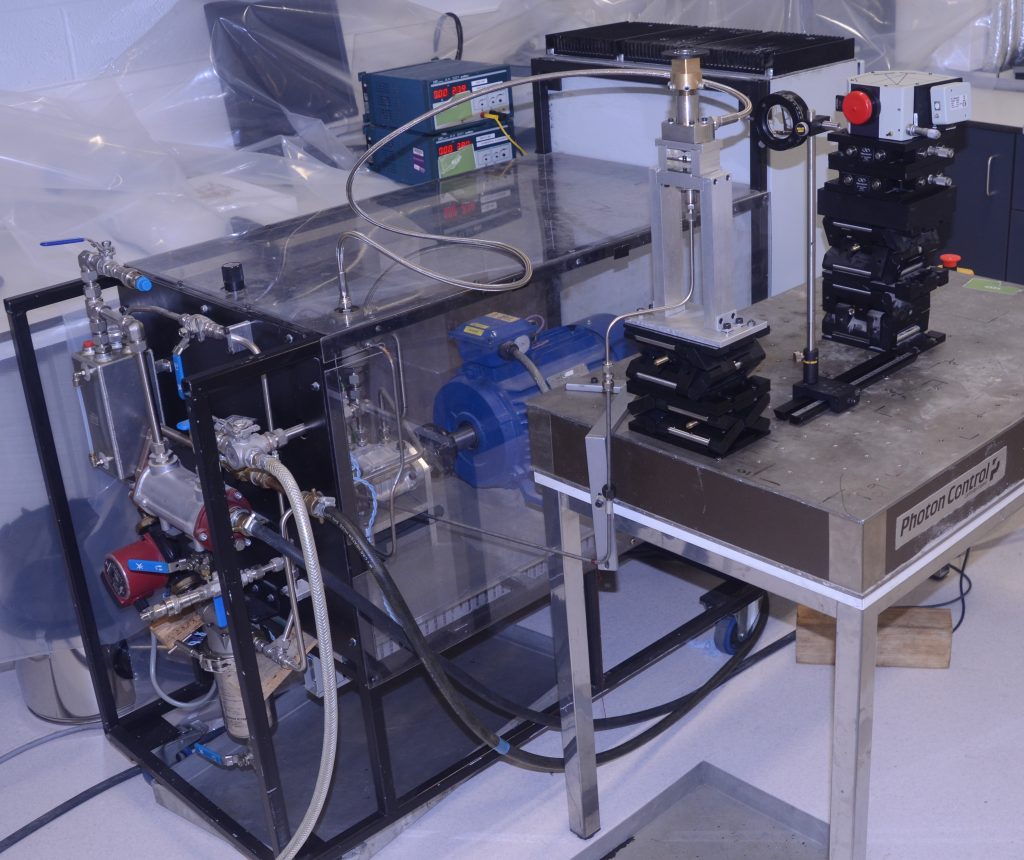

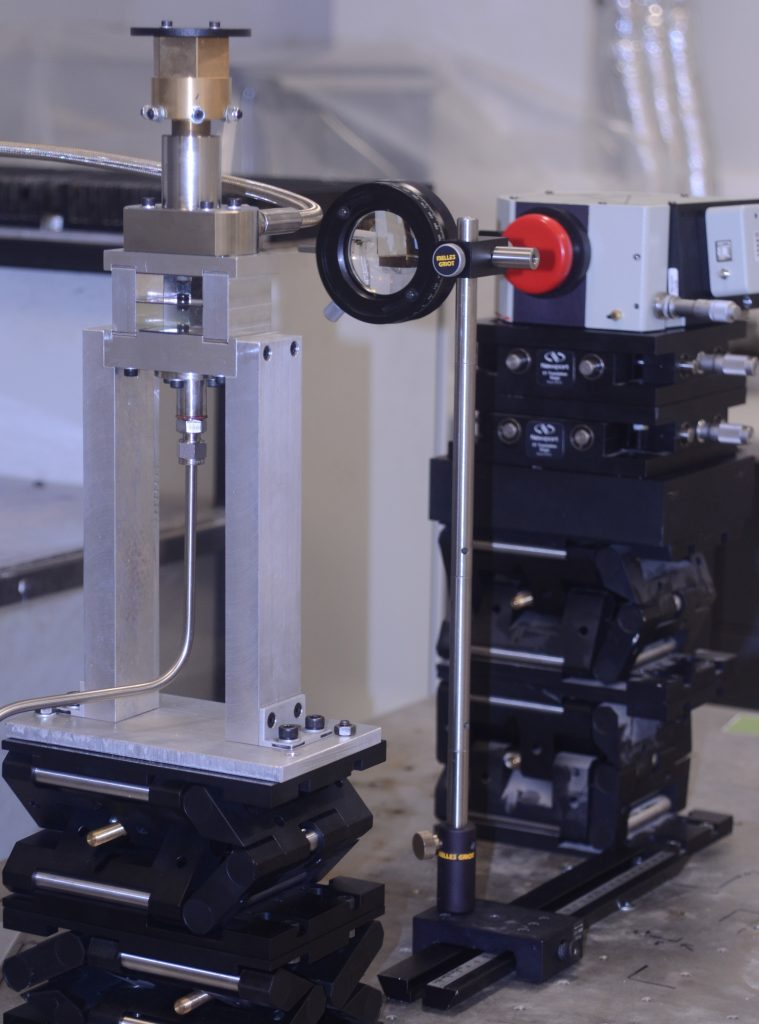

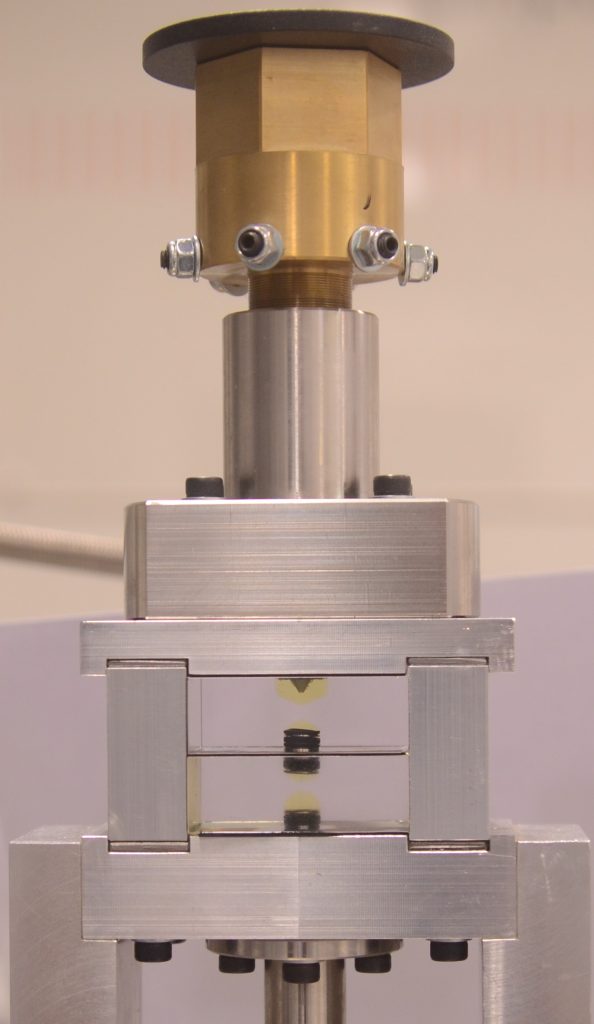

The following Images and Figures refer to recent research work done in an optically accessible model magnetic solenoid operated Diesel injector return valve. The fused silica return valve assembly was micro-machined in Aachen, Germany. It consists of 2 fused silica blocks, with hemispherical and cylindrical holes bored into the blocks. The bored sections are connected via 200 micron and 220 micron nozzle holes respectively. The 2 blocks are arranged together axially, and held within an aluminium cage, with nitrile rubber gaskets located between each face. The blocks were sealed together using a steel sleeve with recesses and nitrile o-rings. The assembly is capable of being exposed to up to 500 bar upstream fuel pressure.

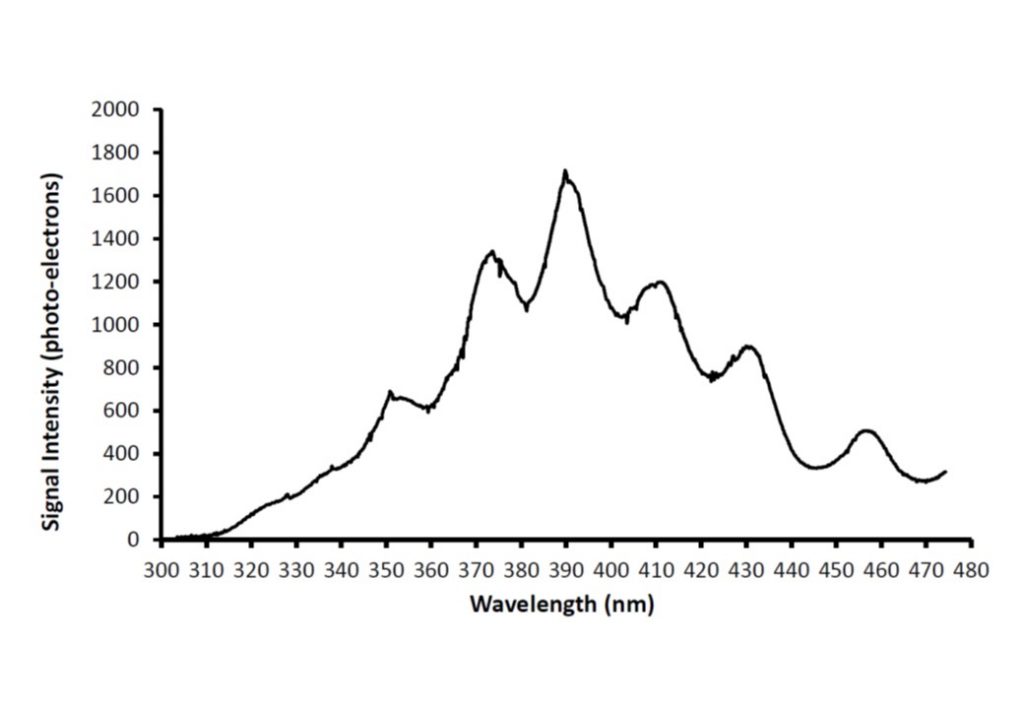

During early stage imaging of the Diesel flow occurring in the model pressure control system, we noticed light originating from the entrance to the second nozzle hole. Further investigation of this led to our paper “Hydrodynamic luminescence in a model diesel injector return valve” in International Journal of Engine Research (https://doi.org/10.1177/1468087419870421, Hydrodynamic Luminescence in a Model Diesel Injector Return Valve (researchgate.net). The luminescence appears to be caused by tribological stress induced in the Diesel fuel at the entrance to the second nozzle, and is dominated by the three spin-allowed π* → π transitions (1E1u → 1A1g, 1B1u → 1A1g, and 1B2u → 1A1g) in the aromatics comprising the Diesel, which are subject to bathochromic shifting through orbital conjugation.